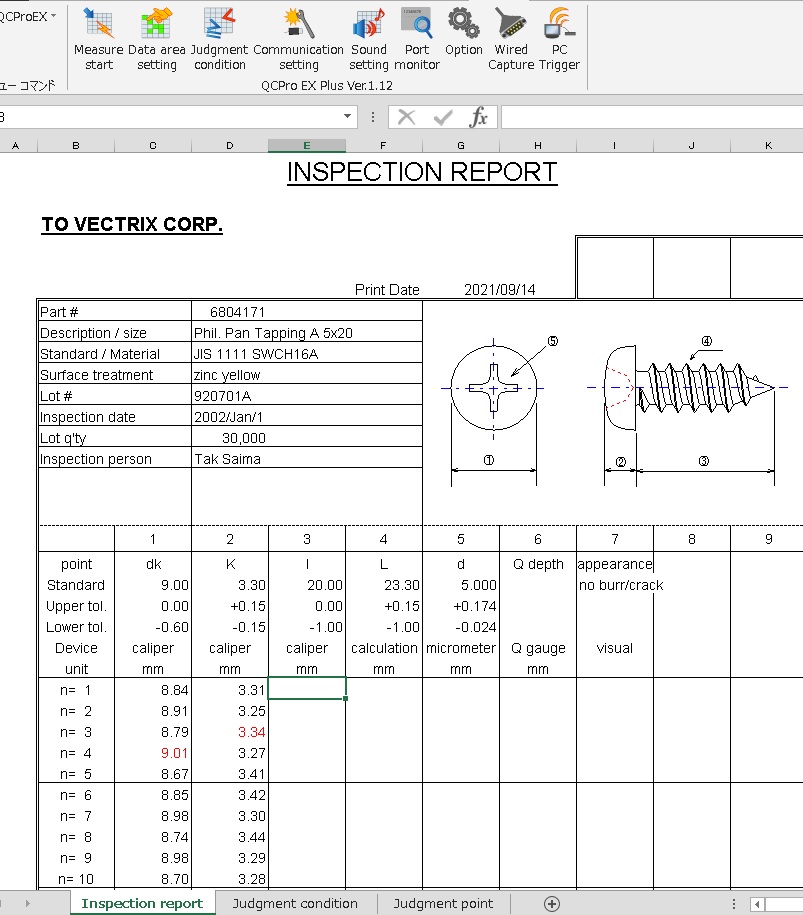

QC PRO EX Plus

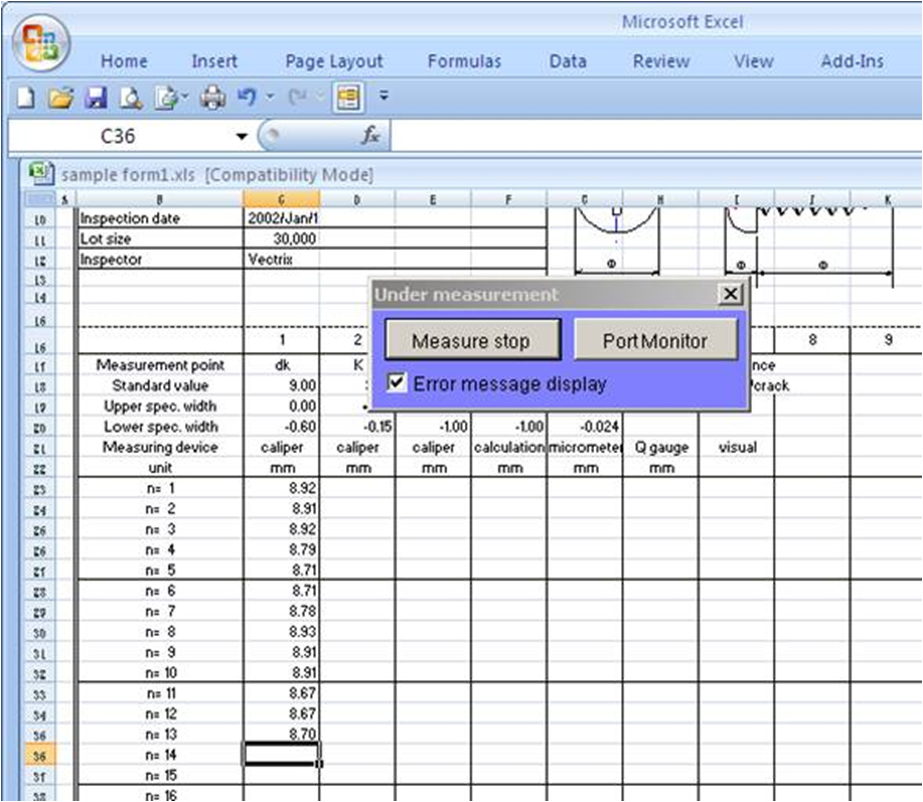

“QC PRO EX Plus” is an advanced Excel add-in software which imports measured data from TelemeasureII via Data receiver into Excel sheet.

It has additional functions compared with former software:QC PRO EX.

- Common installer for Excel 32bit and 64bit edition

- Available for non admimistrator acount user

- Automatic add-ins registration

- OK/NG judgement for keyboard input and result of formula.

- Icon menu realized outstanding operability.

- Data import from RS-232C measuring device with bilateral interface using wired cable (paid option)

- PC trigger function(paid option)

- Patlite output(paid option)

- English/Japanese/Chinese/Korean selectable

- Realized import time reduction for mass data by speed up and “Import in active cell” function.

- “Overwrite data” function.

- OS:Windows 10/11(Home/Pro)

- Excel:2013~2021(64bit/32bit)/365 (for 2013~2021)

*Office App Store version is unavailable. - CPU:Intel(R) Core i5 or more

- Hard disk:more than 2GB space in C drive unit

- Microsoft .Net Framework 4.6.1 or later

- Memory:4GB or more

Agreement on the use of software license

QC PRO EX Plus demonstration movie

QCPRO EX Ver.5 Sales stop at end of Nov. 2021

QC PRO EX is an Excel Add-in software to read measured data directly from measuring device with Transmitter into Microsoft Excel. To use QC PRO EX, PC with Windows & Excel, and Telemeasure hardware are required. Also, your current Inspection report based on Excel sheet can be used.

Telemeasure is a wireless measured data importing system consisting of handy Transmitter and Data receiver. The transmitter is designed to transmit measured data received from digital measuring devices by FM radio wave. The Data receiver forwards the measured data to PC after receiving from transmitters.

- Only measuring operation makes possible to input data into cell, then inspection report is made immediately.

- Indicate data reception and OK/NG judgment by PC sound and NG red character.

- By Data area and ID No. setting function, input area, input sequence and ID No. are set.

- By Communication setting function, direct input without Telemeasure is available.

- Inspection report currently in use of Excel form (including Excel micro and function) is available.

- OS: Windows 10 or 11 of English edition (Home/Pro)

- Memory:4GB or more

- Excel: 2013~2021 of English, 32-bit edition

Excel: 2013~2021 of English, 64-bit edition.

(When OS or Excel is out of Microsoft support, function of QCPROEX is not guaranteed.) - In case of Japanese, Chinese Windows or Korean Windows and Excel, please install QC PRO EX of Japanese, Chinese or Korean version, respectively.

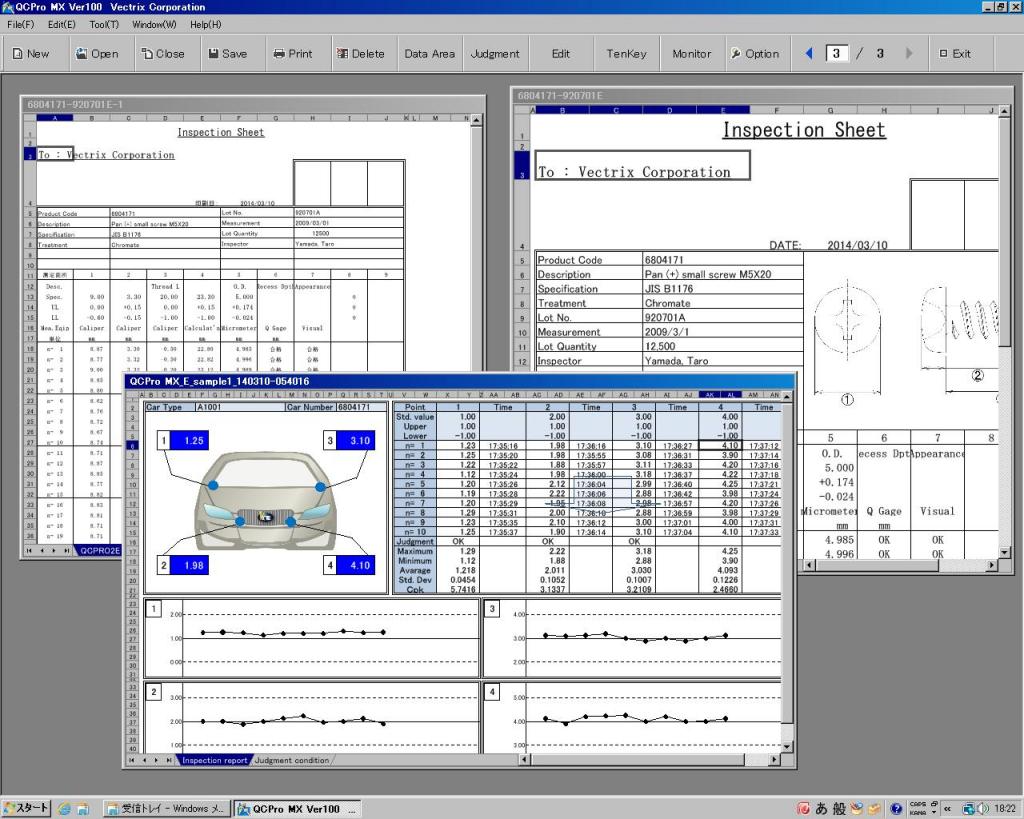

QC PRO MX

Application software importing measured data transmitted from Telemeasure into Excel Sheet.

- Excel inspection report of your company is just available without any modification.

- Same time input to plural inspection reports for one PC (ID offset function)

- Prompt search for inspection item by barcode

- Easy understanding automatic OK/NG judgment: sound, NG red color and Patlite signal

- Also available for Windows tablet PC

- Easy touch panel input of numeric value by TenKey function

- Unnecessary to install Microsoft Excel

- Language selection from English, Japanese, Chinese or Korean is available.

- Visual measuring tendency by Control chart

- Human error & inspection time reduction and cost-cut by using Telemeasure

- OS:Windows 10 or 11(Home/Pro)

- Excel:2013~2021(64bit/32bit edition) for making definition file.

- CPU:Intel(R) Core (TM) i3 equivalent or later

- Memory:4GB or more

- Hard disk:more than 2GB space in C drive unit

- Microsoft .Net Framework:4.6.1 or later

Agreement on the use of software license

QC PRO

QC PRO is a data base styled quality control software which automatically records, calculates and analyzes measured data corresponding to Statistical Process Control.

QC PRO enables to make inspection reports and various QC control charts speedily and without mistakes.

QC PRO much contributes to reduce time and cost of quality control work.

- Easy operation for person inexperienced to PC

- Customized inspection report form is made by Excel.

- Speedy initial registration before data import using reference function.

- Wireless data import by TelemeasureII reduces input mistakes.

- Real time OK/NG judgment and statistical calculation

- Saving long term mass measured data contributes to trace past data with searching function.

- Able to register measuring information by Japanese, English, Chinese and Korean

- Various optional functions such as Control Chart

- Easy data linking with other factories.

Basic function

1. Preparation

1-1. Preparation of Excel inspection sheet form

Inspection Sheet form for QC PRO is Excel format.

65 kinds of standard Excel form are pre-installed in QC PRO folder.

User can use or customize these forms or create own form.

In each cell enter “form command” such as ?MD_01_01(means Measurement value) from command list in menu “Report Command“.

Because available to also register statistical “form command” such as Cpk, formula and Excel function in Excel form, it is possible to process complicated calculations in a short time.

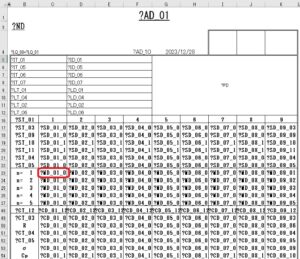

Sample of Excel standard Inspection Sheet form for QC PRO use

1-2. Easy Product – Lot Info. registration

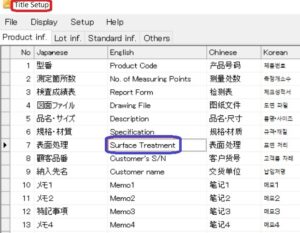

1) Title Setting

Before register Product-Lot Info. , title name is customized by menu “Title Setting“.

Sample of Title setting of Product inf.

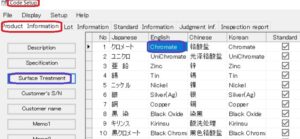

2) Code Setting

Next for each title of Product & Lot information available to resister Code names by menu “Code Setting“.

Sample of code setting of Surface Treatment as Chromate in Product inf.

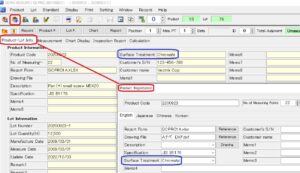

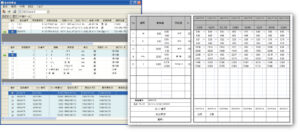

3) Product Registration

Product & Lot information are easily entered or selected from Product/Lot registration.

Sample of Product Registration (right lower) and entered Product Information and Lot Information.

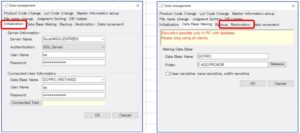

1-3. Data Base setting

Before use QC PRO, user has to set Server Information and Connected User Information (tab: Initialization),

adopts Microsoft SQL Server as data base software.

Then make Data Base by menu “Data Management“(tab: Data Base Making).

2.Wireless data import by “TelemeasureII

Measured data from TelemeasureII transmitter connected measuring equipment will be transmitted to data receiver wirelessly and imported to PC by menu “Inspection business. Product Information Entry“.

By ID No. setting function of transmitter, transmitted data with ID No. able to identify the equipment by ID.

Wired cable import from equipment and CSV file data import from image processor are also available.

2-1 Centralized management by CSV data import

Usually, 3-D measuring device and image processor have their dedicated PC. Measured data should be managed only by the PC.

If these device or processors have CSV output function, QC PRO can import CSV data into common measurement form.

Therefore, QC PRO can import and manage not only size, weight, torqe or hardness but also CSV data centrally.

Measured data from 3-D measuring device (green;CSV format), caliper(red), micrometer(blue)

Measured data from 3-D measuring device (green;CSV format), caliper(red), micrometer(blue)

and indicator(yellow) can be imported into same inspection form.

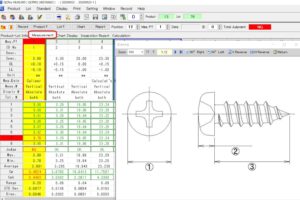

3.Data Measurement and processing and display

3-1. Real time OK/NG judgement and statistical calculation including Cp,Cpk.

Able to easily recognize defective position because NG data are shown red color and NG buzzer sound.

Available to import data without mistakes referencing parts drawing shown on the screen.

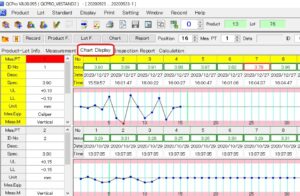

3-2. Time serial display of imported data by Chart Display

Display imported data/time by numeric and graph in time serial.

Available inform tendency to check data stability.

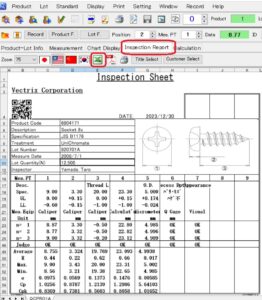

4. Output and convert Inspection Report

Sample of printed Inspection Sheet

Also, Inspection Report is converted to Excel format.

Option functions

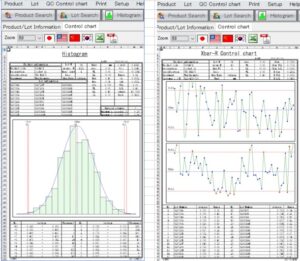

1. Control Chart

By specified measurement point creates statistical graphs from measured data by specified lot units.

Histogram, XBar-R, X-Rs, X and Cpk chart are created.

These charts check control status of manufacturing process and contribute to reduce reject rate.

Sample of Histogram for measurement point:1, 30 lots (left)

Sample of Xbar-R Control Chart for 30 lots (measurement point:1)

Show variation of Xbar (Upper) and R(Middle) for 30 lots. (Right)

Xbar:Average value of the lot

R:Range between the maximum and minimum values in the lot

2. Inspection Autobiography

By measurement point history of statistical data such as min., max.,Cp and Cpk for specified lots are shown.

This function catches variation of measured data and traceability.

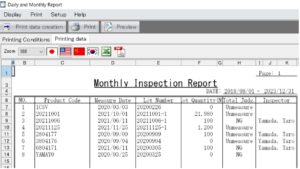

3. Daily/Monthly

Output daily or monthly measured data (Product code, Lot No.,Inspector, Lot quantity and Judgment) as Inspection Report.

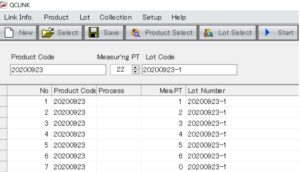

4. QC Link

Created new Inspection Report from Inspection Reports measured by lots (manufacturing process) specifying Measurement points.

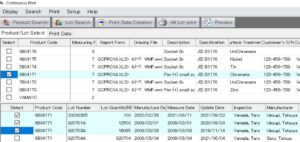

5. Continuous Print

Creates print data of Inspection Reports specifying Lot Numbers all at once.

This function is convenient when prints Inspection Reports of same client or Product Code.

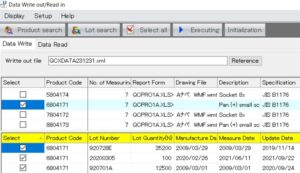

6. Data Read/Write

Specifying Product Code and Lot Number, read in data from file or write out data to file.

This function is convenient when transfers data from local factory to head office .

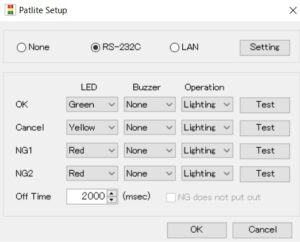

7. Patlite Setting

Available to check data import and OK/NG judgement far from PC.

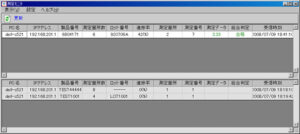

8. Measurement Monitor

Monitoring function which watches measuring status of other PC connected through network.

When execute inspection in all processes, using this function available to catch inspection progress in former process.

it is possible to construct inspection system which can make preparation of later process.

- OS:Windows 10 or 11 (Home/Pro) of English edition

- CPU Intel(R) Core i5 equivalent or later

- Memory:2GB or more ※Recommend 4GB or more

- Hard disk:50GB or more space in C drive unit

- Diaplay:1280 x 1024, 65536 colors or more

- Microsoft .NET Framework:4.6.1 or later

- Database: SQL Server 2014, 2016,2017 or 2019(Standard edition or Express edition)

Agreement on the use of software license

Application in typical user

We are using total 65 sets of QC PRO in various manufacturing processes. Visual chart of QC PRO showing changing points or comparison with past data has much helped us to utilize data effectively. Defect ratio was much improved, customer regards QC PRO with high value. In near future we are going to introduce QCPRO to other factories.

ReceiverCom

“ReceiverCom” is a software importing measured data transmitted from Telemeasure

into active field of application software for core system operated under Windows.

At the same time as importing measured data,

available to import control code such as “Enter” & “Tab”.

Therefore possible to continuously import while moving item.

・Available to use operation screen of user’s system without any change.

・Unnecessary to make complicated communication program.

・English/Japanese/Chinese/Korean selectable

・Microsoft .Net Framework 4.6.1 or later

Agreement on the use of software license

Annual support for support member of QCPRO series

- Remote support by “TeamViewer” and support desk(*)

- Discount sales of version up software and operation service at user site

- Re-issue of software CD-ROM and operations manual

- Supply latest updated software edition

*In the following cases software function and recovery are not guaranteed.

Use OS or Office out of Microsoft support.

OS or machine (PC printer, etc.) trouble