Defacto Standard!

-Exclusive to Small screw & Tapping screw-

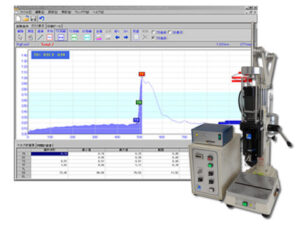

Connecting to your PC, screw torque is graphically analyzed.

- Test by actual workpiece and fastening condition。

- Prompt display of target fastening torque with tolerance by statistical method

- Best decision of hole dia.,kind and fastening condition for tapping screw

- Available for PC on the market by USB connection

- Prompt Test Report generation with torque graph

- Excel output of torque data

- Graphical display of rotation angle after seating

- Available to add Axial force option

- Available to tighten by specified torque using 2 steps tightening function

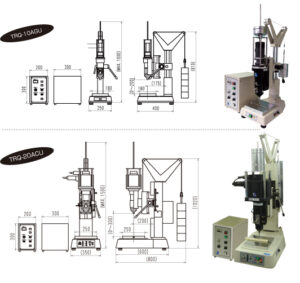

Product type

1.AC Servo Motor type (0.5Nm, 1Nm, 2Nm, 5Nm, 10Nm, 20Nm,50Nm)

AC Motor Type with non-step rpm adjustment (Max.3,000 rpm)

TRQ-0.5ACU, 1ACU, 2ACU, 5AGU, 10AGU or 20ACU,50AGU

| AC Servo type | |||||||

|---|---|---|---|---|---|---|---|

| Type | TRQ-0.5ACU | TRQ-1ACU | TRQ-2ACU | TRQ-5AGU | TRQ-10AGU | TRQ-20ACU | TRQ-50AGU |

| Maximum torque N・m | 0.5 | 1 | 2 | 5 | 10 | 20 | 50 |

| Main drive | 200W | 400W | 400W | 400W | 400W | 3.5KW | 3.5KW |

| Revolution (r.p.m) | 1~4500 | 1~4500 | 1~4500 | 1~1200 | 1~1200 | 1~3000 | 1~1000 |

| Reduction ratio | 1:1 | 1:1 | 1:1 | 1:5 gear | 1:5 gear | 1:1 | 1:5 gear |

| Power | AC100V | AC100V | AC100V | AC100V | AC100V | 3P200V | 3P200V |

| Thrust load N | 0~30 | 0~50 | 0~100 | 0~150 | 0~200 | 0~350 | 0~350 |

| Bit holder | HIOS-H4 | HIOS-H4 | VESSEL hexagon 6.35 | VESSEL hexagon 6.35 | VESSEL hexagon 6.35 | VESSEL hexagon 6.35 | VESSEL hexagon 6.35 |

2.Electric Driver Type (1Nm, 2Nm, 5Nm)

Electric Screwdriver Type used in work site

TRQ-1DRU, 2DRU or 5DRU

| Electric Driver Type | |||

|---|---|---|---|

| Type | TRQ-1DRU | TRQ-2DRU | TRQ-5DRU |

| Maximum torque N・m | 1 | 2 | 5 |

| Mian drive | DLV7120 | DLV7130 | DLV7151 |

| Revolution r.p.m | 1,000 | 1,000 | 700 |

| Reduction ratio | 1:1 | 1:1 | 1:1 |

| Power | AC100V | AC100V | AC100V |

| Thrust load | 30 | 40 | 50 |

| Bit holder | HIOS-H4 | VESSEL Hexagon 6.35 | VESSEL Hexagon 6.35 |

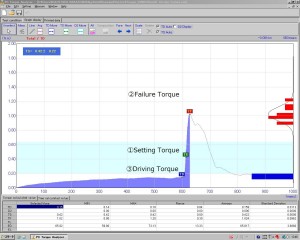

Basic Driving test

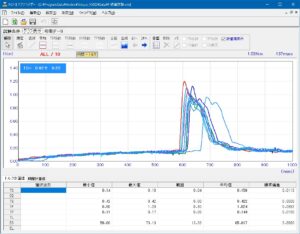

1.Graphical display of torque characteristics for tapping screw

Prompt display of Driving Torque (TD) by automatic search

- Prompt visual display of Setting Torque (TS) with tolerance by statistical method

TS=(TSmax+TSmini)/2

TSmax=AVERAGE(TF)-(k×STDEVP.(TF))

TSmin=AVERAGE(TD)-(k×STDEVP.(TD)) - Histogram display of Failure Torque (TF) with normal distribution graph

- Histogram display of Driving Torque (TD) with normal distribution graph by its automatic detection

- X-axis of graph:Time(unit;ms), Y-axis:Torque value

Variable setting of number of significant figure and decimal figure - Variable scale setting enables visual graph and partial enlargement of graph

Torque data analysis screen

2."Superposition" & "Composite" graph from multiple torque curves

2 types of torque graphs from multiple sample data

①Abnormal data detection from "Superposition graph"

②Torque characteristics comparison with other tapping screw by "Composite graph"

3.Torque test under actual tightening condition !

Torque test is possible by actual assembling work

①Making of bothersome test piece is unnecessary

Other torque analyzer requires test piece, the result is different from actual assembling work.

②High speed revolution torque test

Other torque analyzer tests by low speed such as several revolutions per minute.

Actual tightening speed is much faster than the low speed.

This torque analyzer is able to test by high-speed revolution under actual tightening condition.

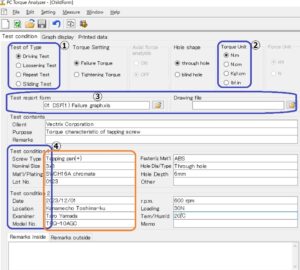

4.Easy setting of test condition and its view

Test condition at a glance

①Selection from 4 kinds of tests Driving test, Loosening test, Repeat test or Sliding rest

②Selection from 4 kinds of units N・m, N・cm, Kgf・cm or lbf・in

③Selection from 30 kinds of test reports

④Various test conditions

Other tests

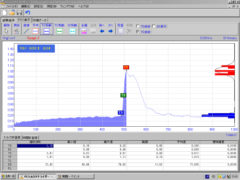

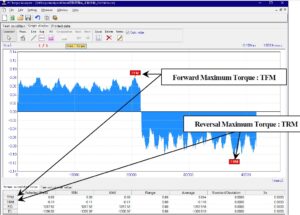

1.Loosening test

Detecting loosening torque automatically, display as minus torque.

Loosening of fastener is caused by reverse rotation, not driving the recess but mainly right-angle vibration to the axis.

Therefore to execute the loosening test, by as possible as low r.p.m loosens fastener showing graph of loosening torque.

Torque Analyzer automatically analyzes loosening torque characteristics, including detecting start loosening torque TL (Loosening Torque)

※Loosening torque curve at low speed (10 r.p.m)

2.Repeat test

Automatic alternative test of driving and loosening

Tapping screw is said to be unsuitable for repeat use.

Some users request repeat test for tapping screw as one of its quality characteristics.

PC Torque Analyzer can execute repeat test by automatically changing tightening and loosening test alternately.

Repeat test data are shown on one graph first tightening then loosening torque.

Repeat test is useful function for measuring limit of repeat use of tapping screw. ?

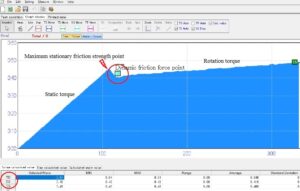

3.Over-driving (Re-tightening) test

By over-driving test, it is possible to analyze and measure actual over-driving torque.

To measure the torque of already tightened screw, PC torque analyzer can execute over-driving test by low speed (10 r.p.m. or less).

In the torque graph of over-driving process, PC torque analyzer detects 2 inflection points.

These points are maximum stationary friction strength point and dynamic friction strength point which are appeared in the graph when screw starts to rotate again by slow over-driving.

The dynamic friction strength torque is actual tightened torque.

Over-torque test is useful function for measuring "Creep".

※ This test is available only for r.p.m. adjustable AC servo type

4.Sliding test

Available to measure sliding torque at forward/reverse rotation of screw.

Other functions

1.Torque calibration on working site

By attached calibration kit, torque calibration by yourself is available.

Saving the calibration history helps easy calibration control.

By calling the history, it is possible to skip calibration work such as re-install to PC.

2.Prompt Test Report generation with torque graph

Bothering graph edition such as magnification, reduction or cut & past is unnecessary.

Printing test report including test condition set before test is available.

30 kinds of Excel report format are available.

Free edition to Excel format including graph is available.

Torque graph is automatically sized according to test format and pasted by bmp format.

Test report is saved by Excel format in PC, therefore it is possible for PC not installed Torque analyzer software to display, print test report or send it by email.

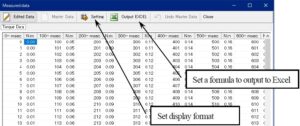

3.Torque data output by Excel or CSV format

Digital sampled torque data are converted to Excel or CSV format.

Torque data are sampled every 1/1000 sec and outputted to PC, therefore other analysis software can use these data.

★Symbols used in the torque analyzer (basic functions)

・TD (Driving Torque) :When looking at the torque values of measured data in a time series, this is the point at which the torque becomes maximum on the slope where the torque begins to be applied suddenly.

・D2 (Driving Torque 2):The point at which the slope of the torque increase in the retightening test temporarily drops and then torque begins to be applied again.

・TP (Plat Torque):

[For through holes] The point at which the torque fluctuation from the torque value 1 millisecond earlier becomes flat when tracing the torque value of the measured data back from point TF.

[For blind holes] Same as T.D.

・TS (Setting Torque):The range of appropriate torque values for screw tightening is calculated from the statistical data of the failure torque test, and the midpoint of that range is designated as TS.(In the case of a tightening torque test, the point at which the torque is maximum in the test data is defined as TS.)

・TF (Failure Torque):The point where the torque is maximum in the failure torque test

・TL (Loosening Torque):The point where the torque is minimum in the loosening torque test.

・ED (Driving Energy):Accumulation of torque values ??measured every 1 millisecond from the start of the test.

・EL (Loosening Energy):Accumulation of torque measured from TL to the end of the loosening torque test.

Axial Force Analysis Function (Option)

Required software;

・Paid Axial option of PC Torque Analyzer software Ver.5

OS: Windows 11/10(Home/Pro)

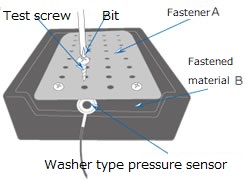

Required hardware;

・Washer type pressure sensor

・Torque-axial force 2 axes amplifier AD converter, type: TFA-USB

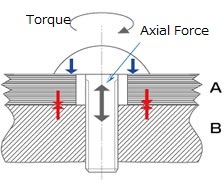

“Axial force” is defined as force that screw is pulled by fastening.

That is, adhered force between fastening material A and B by screw.

“Axial force” is also called as screw tightening force or fastening force.

Unit of “Axial force” is written as N or kN.

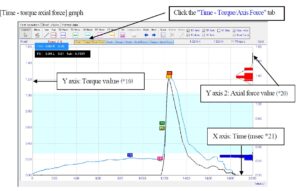

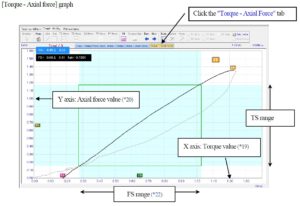

←Left graph is Torque Axial force-Time data under the actual tightening condition.

Mating material:φ4 hole 1mm thick iron plate+ABS resin

Pilot hole・Shape:φ2.6 through hole 6mm

Female screw length:6mm

Kind of screw Cross hole Pan Tapping B

Nominal diameter of screw:3×12

Material・Surface:Trivalent chromate (SWCH18A)

Revolutions speed :300r.p.m

Inserting washer type pressure sensor between fastening material A and fastened material B, measure axial force.

Graph torque (X axis) and axial force (Y axis) data together obtained.

Show torque (X axis) and axial force (Y axis), therefore available to understand relation between torque and axial force.

Show torque (X axis) and axial force (Y axis), therefore available to understand relation between torque and axial force.

Within TS (Setting Torque) range of best tightening torque,

Relation between corresponding to FS (Setting Axial Force; best tightening axial force) and TS is almost linear.

Therefore, within this TS range, next formula holds true.

T=uk・F+TP

T: Torque(N・m) F: Axial Force(kN) TP:Plat Torque(N・m)

uk: Unique torque coefficient torque coefficient under real tightening condition;Vectrix advocates)

In the upper graph uk=0.766, TP=0.17, “Torque-Axial force” formula is T=0.766×F+0.17.

Using “uk” obtained under real tightening condition, if condition is same, only measuring torque (T) available to calculate tightening axial force (F).

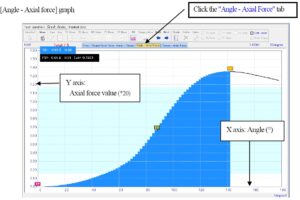

Graph tightening angle of screw from seating to failure.

Graph Axial force (Y axis) against Angle (X axis).

Graph Axial force (Y axis) against Angle (X axis).

In this graph understand tightening angle from seating to failure.

In left graph failure occurs at angle 115.2°, setting axial force is 64.8°.

In a similar way available to graph “Angle-Torque”.

・AC servo motor type only

Required hardware;

Washer type pressure sensor

Washer type pressure sensor

Sensing method: Crystal piezoelectric type

Maker: Kistler

| Screw diameter

(Washer type) |

Inner

diameter |

Outer

diameter |

Thickness | Measuring range. |

| mm | mm | mm | kN | |

| M2.6 or less (9130B) | 2.7 | 8.0 | 3.0 | 0~3 |

| M3~M4 (9132B) | 4.1 | 12.0 | 3.0 | 0~7 |

| M5~M6 (9133B) | 6.1 | 16.0 | 3.5 | 0~14 |

* At shipping attach inspection report recorded calibration digital value.

* Please use long screw with length J90 or 3.5mm (thickness of sensor) as test screw.

Torque-axial force 2 axes amplifier AD converter, type: TFA-USB

Torque-axial force 2 axes amplifier AD converter, type: TFA-USB

| Power | AC100V |

| Data input | Torque & Axial force 2 data |

| (Only torque available) | |

| Data output | USB output |

| Resolution:16 bit | |

| Size | W185×H80×D150mm |

★Symbols used in the torque analyzer (Axial Force option)

・FS (Setting Axial Force): The?appropriate torque value and axial force range for screw tightening is calculated from the statistical data of the failure axial force test, and the midpoint of the appropriate axial force range is designated as FS.

(In the tightening axial force test, the point where the axial force is maximum is called FS.)

・FF (Failure Axial Force): The?point where the axial force is maximum in the failure axial force test is defined as FF.

・uk(Unique torque coefficient): [Torque - Axial force] The torque coefficient, which represents the slope of the graph, is called uk and is calculated from statistical data on torque and axial force in failure axial force tests.

Recommended PC circumstances.

OS;Windows 10/11(Home/Pro) of Japanese, English or Chinese edition

Microsoft .Net Framework:4.6.1 or over

Main Memory; 8GB or over

Interface between PC & Main body: USB2.0

*Software of PC Torque Analyzer is provided by Japanese, English and Chinese edition.

Agreement on the use of software license

SUPPORT

Annual support for support member

1.Remote support by "TeamViewer" and support desk (*)

2.Discount sales of version up software and operation service at user site

3.Re-issue of software CD-ROM and operations manual

4.Supply latest updated software edition

*In the following cases software function and recovery are not guaranteed.

Use OS or Office out of Microsoft support.

OS or machine (PC printer, etc.) trouble

User examples

Fastener user

- Decision of standard fastening operation at assembling line.

- Torque analysis for new product

- Torque analysis for hole dia. decision

- Torque analysis for fastening troubles

- Torque test of purchased screws and instruction of setting torque at fastening work

Fastener manufacturer

- New screw development and comparison of competitor screws

- Making advertising and technical materials of products at new customer cultivation

- Making technical materials and proposal for customer

- Preparation of Torque Test Report at shipping

- Analysis and countermeasure against fastening troubles

Fastener trader

- Making technical materials and comparison of competitor screws for new customer cultivation

- Fastening data collection and analysis for new screw development

- Making technical materials and proposal for customer

- Evaluation and technical advice to fastening manufacturer

* About other consults, please contact with Vectrix Corporation.